Process

- Ti/ALD–TiN

- ALD-TiN

- ALD-W

- TOT (TiN/Ox/TiN)

Applications

- Capacitor

- Worldline

- Plugs

- Metal contact

- MG

Introduction.

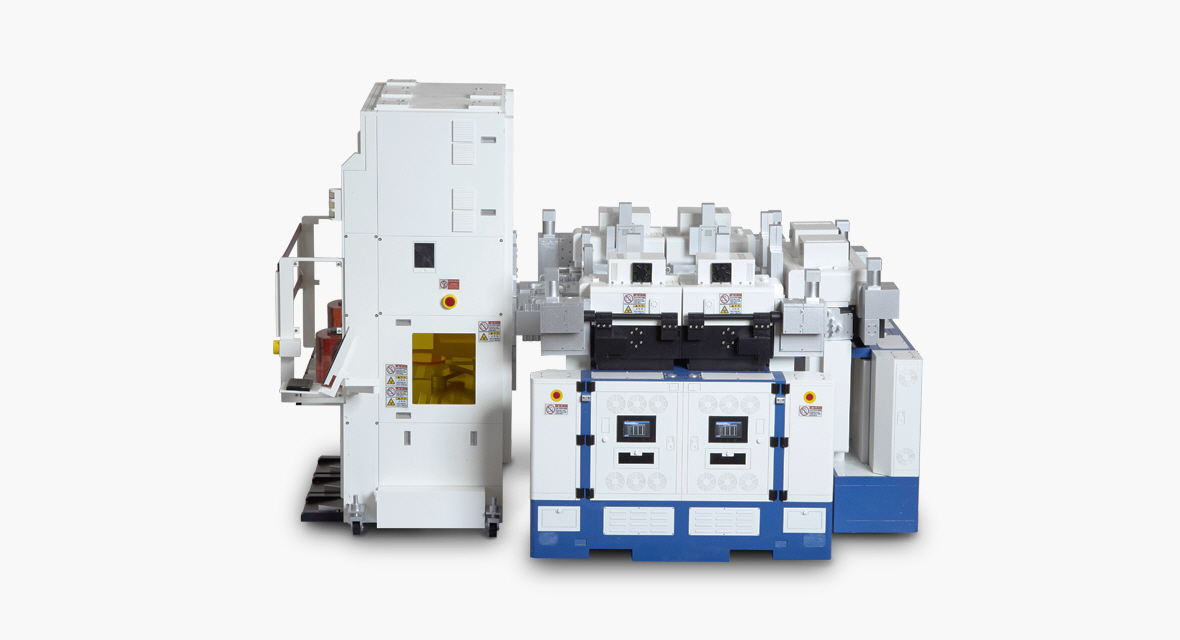

NOA has its one and only unique feature that can integrate different metal processes andstand-alone process. Depending on users, NOA can extend its platform for different needs,which could be integrated different processes like Ti/TiN, Tungsten, and Clean steps intoone single system. This allows less FAB costs and space savings for manufacturers.

Since technologies move to smaller technology nodes, it can be very difficult to completelyfill narrow contacts, vias, plugs and word lines. The NOA can provide solution for ALD-tungsten process which provides excellent gap-fill ability with very low fluorine content and lowresistivity compared to pre-existing tungsten processes.

Technology.

NOA SYSTEM deposits Tungsten film which is used for conductive features like contacts,vias, and plugs on a chip and it is also possible to form TiN(Capacitor Electrode for DRAM)and TiN(Contact barrier metal for DRAM/Logic/3D NAND). As device nodes scale down, conventional CVD Film deposition is limited. NOA system enables integrated metal processes.

Features.

1. Able to Configure In-line Process Modules For Optimum Integration

2. Higher UPEH with Smaller Footprint (6 to 10 Process Modules)

3. Excellent Reliability ALD

4. Excellent Step Coverage (> 95%)

5. Excellent Gap Fill Performance

6. Uniformity Unif (ALD TiN < 1%)

7. Low Cl Content (ALD TiN < 0.5at%)

8. Low F Content (LFW <5.0E17atoms/cc )